Biolab: Silkworm-derived Nonwoven Fabric

October 20th to 24th, 2019

Biolab of the Graduate School of Design at Kyushu University was launched in 2019 and is currently engaged in joint research with various researchers from within and beyond the university. Our wide-ranging research adopts multiple perspectives on the relationship between intelligence and life, including bio-aesthetics, artificial intelligence, bio-art, synthetic life, and DIY bio, as part of our efforts to “develop the pedagogy for next-generational design education (creative education).”

Ms. Terumi Ikenaga, a PhD student from the Graduate School of Agriculture at Kyushu University, is currently conducting experiments at Biolab involving threads that silkworms spew out. This experiment explores the design-related possibilities of silkworm byproducts such as their threads and membranes as well as their unique material-shaping process.

Click here to learn more about the experiment so far

Silkworm flat-spinning experiment

Designing a composite material made from nanocellulose×silk filaments

What is the impact on the ecosystem and the environment when we purchase a pair of T-shirt or jeans that we have casually chosen?

To produce a T-shirt made from 100% cotton, 2,700 liters of water is needed to cultivate the cotton plants. This is the equivalent of 900 times the amount of water a person drinks in a day.

One quarter of the total amount of pesticides used globally can be traced to the cultivation of cotton, with the surface of the world of organic cotton grown under pesticide-free conditions accounting for less than 1% of the total cotton production area.

For instance, cotton used in jeans production is cultivated in Uzbekistan and shipped to India to be spun into yarn, before being transported to Morocco for dyeing and finally sold in France. Cotton like this is transported over a distance of around 65,000 km from start to finish, resulting in the emission of 1.2 billion tons of greenhouse gases from the production and transportation of cotton every year[1].

In addition, among the chemical substances used in fabric processing during the production of clothes, the compounds of NPEs(nonylphenol ethoxylates) most widely used as surfactants degrade into the toxic NP (nonylphenol) after being discharged in wastewater. NP that is released into the sea does not break down; instead, NP is known to be bioaccumulative, and it been detected in human tissue where it is able to act as a hormone disruptor, after magnifying through the food chain [2][3].

In view of this, even the production of T-shirts and jeans from cotton, which is a natural fiber, has a severe impact on the ecosystem and the environment.

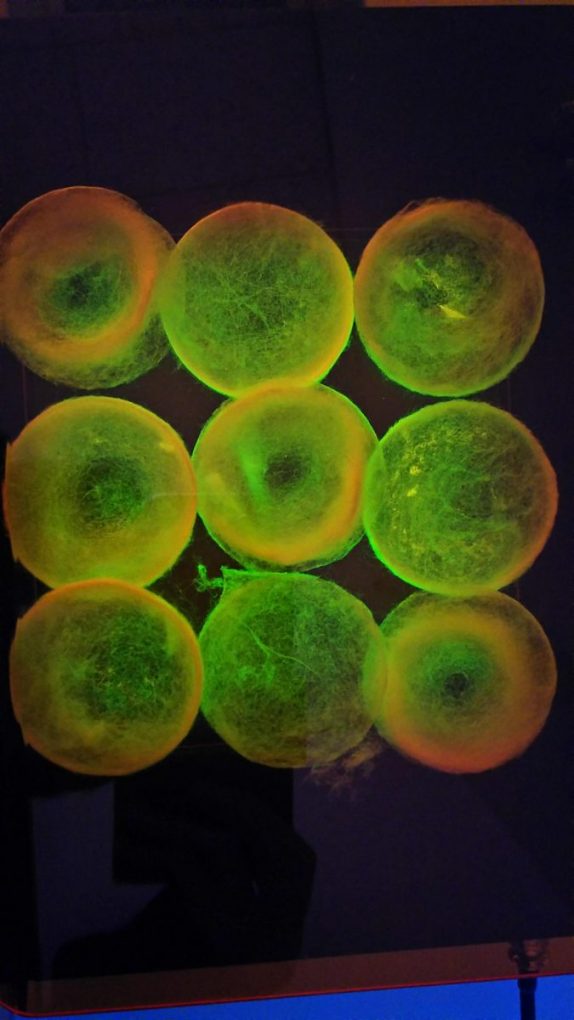

The first step of designing a composite material from nanocellulose and nonwoven fabric derived from silkworms was the production of nonwoven fabric parts. As this nonwoven fabric was created with the vitality and spinning technique of silkworms, it took shape without the emission of any greenhouse gases. Since the silkworms finished spinning silk after 2 to 4 days, the nonwoven fabric was ready after around 30 days, which include the 25 days required for the rearing of silkworms. The previous experiment demonstrated that silkworms spun silk more uniformly over a circle than a square, and we successfully produced a large amount of circular and hexagonal nonwoven fabric.

After consulting with the Institute of Genetic Resources of the Graduate School of Agriculture at Kyushu University (Professor Yutaka Banno), we conducted the experiment using the “b32” silkworm strain that was recommended for the purposes of this research. This silkworm strain has a gene known as San (Spinning of Sankenshi) which ensures there is no reduction in the synthesis and secretion of silk proteins even in cases of flat-spinning. In addition, this silkworm strain is supported by the National Bioresources Project (NBRP) of the Ministry of Education, Culture, Sports, Science and Technology, and is stored at Kyushu University.

Silkworms normally have a habit of metamorphosing into pupae in individual cocoons, but when they were placed in an environment where that is not possible, they wandered around more than usual and left behind extremely intriguing three-dimensional trails of silk threads in a swirling or wave-like pattern on the circular or hexagonal disc, whose structure cannot be reproduced by weaving.

In addition, when silkworm cocoons are spun into yarn and made into fabric, a major component protein of silk known as sericin is typically removed in the process. The removal of sericin turns the threads made from natural yellow or green cocoons to white, which must then be re-dyed using chemicals after the removal process.

However, nonwoven fabric produced from the flat-spinning process does not require sericin to be removed. Therefore, the carotenoids (yellow) and flavonoids (green), components of sericin remain in the threads, which can be used to showcase the natural colors of cocoons without artificial dyes.

Traditionally, the silk production process requires the silkworm pupae in cocoons to be killed when making silk threads from the cocoons. However, in the case of flat-spinning, it is not necessary to kill the pupae, which allowed us to collect a large number of next-generation silkworm eggs in the course of this experiment.

However, the nonwoven fabric produced in this experiment tends to come apart more easily and is less tangling strength than woven fabric. As such, we plan to conduct further research on non-decolonization and enhancing the adherence of nonwoven fabric by combining it with nanocellulose (ACC nanocellulose developed by Kondo Laboratory of the Graduate School of Agriculture at Kyushu University), a material that is capable of adhering to fiber and retaining pigments.

[References]

[1] https://www.youtube.com/watch?v=3DdU7c66E9g

[2] Dirty Laundry 2 : Hung Out to Dry Unravelling the toxic trail from pipes to products, Greenpeace international, 2011

[3] Les dessous toxiques de la mode, Greenpeace international, 2012

Date

October 20th to 24th, 2019

Venue

Biolab, Kyushu University Ohashi Campus

4-9-1 Shiobaru Minami-ku Fukuoka Japan

Member

- Terumi Ikenaga Graduate School of Agriculture, Kyushu University

![九州大学イノベーションデザインネクスト[KID NEXT]](https://www.kidnext.design.kyushu-u.ac.jp/wp-content/themes/kidnext/img/logo_header.png)